@steverugi said:

Hi @Nigel

I am keen to hear the forum members' thoughts on how timber framed, or metal framed walls will in-fill insulation is handled IFC wall material layers.

Here in Aotearoa NZ we typically build houses and smaller buildings using 'light timber framing' similar to parts of Australia and USA.

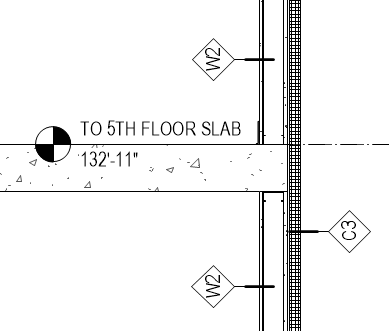

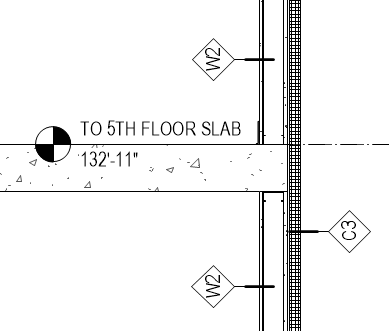

The question is what is good practice in IFC? ![]

thank you in advance :)

interesting topic!

I would gladly extend the request to other parts like: what's best IFC practice for foundations or floors, for instance, or when it comes to walls if plaster is together with blocks or separate covering layer instead..

I understand it depends on several factors but it would be useful to have an exchange on it I think

I can prepare an example of how I'd usually IFC the elements in my takeoff models

The approach you take can vary based on the project and construction methods. In my recent project, I utilized a method that distinguished between "wall types" and "covering types." A "wall type" could refer to a complete wall, including its coverings, or just the structural/framed part, excluding coverings. On the other hand, a "covering type" pertained to the finished covering including its fixing system.

For walls, I found it beneficial to separate coverings in the following situations:

-

Structurally Engineered Components: When a wall included a structurally engineered component, such as concrete or core-filled blockwork, separating the coverings allowed for a clear delineation between disciplines (this also relates to foundations). This approach helped avoid redundant documentation, reducing the risk of errors.

-

Height Differences: In cases where there was a required height difference, particularly in exterior situations, the "wall type" extended from slab to slab, while the "covering type" covered the slab edge and continued up multiple stories. This separation ensured that each component had the correct height, didn't conflict with the floor slabs, and ensured the exterior precisely aligned over multiple stories.

By conditionally separating "wall types" and "covering types" I was able to maintain a relatively condensed wall and covering schedule while being able to accurately cover a variety of conditions.

For floor, roof, and ceiling types, I used a similar conditional logic. Except, rather than needing to control the heights differently, I needed to control their extents on the horizontal plane differently.